As wheat beers provide the overarching focus in Beer & Brewer‘s current Autumn edition, our resident home brew guru John Palmer guides you through your next brew day harnessing the grain.

There are lots of articles on the various wheat beer styles and lots of opinions on what is most important for success. As you may know, I have a top five list for brewing great beer:

- Sanitation

- Yeast management

- Fermentation temperature control

- Boil

- Recipe

Brewing a great wheat beer, whether it’s a hefeweizen, dunkelweizen or weizenbock, follows these same rules and guidelines for brewing any other style of beer. Weizens are simple beers, and by simple I mean that the grain bill is not complex, there are very little hops used and the malt and fermentation characters need to be well balanced for the flavours to really shine. In other words, a small flaw is easily noticed.

So, looking at the list above, you can see that having good sanitation is paramount. There is not much hop character to keep spoilage or souring bacteria at bay. Next, these beer styles rely on their fermentation character for much of their flavour – the famous banana and clove aromas and flavours. These characters are entirely dependent on the fermentation, and if you want consistent wheat beers, you must have consistent fermentations. We will discuss fermentation more in a minute. The fourth point is the boil. Traditionally, or perhaps I should say, “in the olden days”, the wort would be given a longer boil, 1.5 to 2 hours to minimise DMS and precipitate as much protein as possible. A 90 minute boil is probably still good advice to minimise the DMS precursor from the pale wheat and pilsner malts.

This brings us to the recipe. The delicate yet full bready malt flavour of these beers is the backbone of the styles. The fermentation character is important, but if there is no malt to hang it on, it falls flat. Therefore, the finest wheat and pilsner malts are necessary to build this essential big soft bread character. The wheat to barley malt ratio is typically 60:40, although 50:50 and 70:30 also occur. Please note that this is malted wheat, i.e. wheat malt, not unmalted or flaked wheat. Oat or rice hulls should be included in the grist because wheat doesn’t have a husk-like barley. I recommend at least 150 to 200 grams for a 19 litre batch. My friend Gordon Strong recommends a full pound (450g) for a five gallon batch, so don’t skimp. These will greatly aid lautering flow and yield.

The mash schedule

This doesn’t usually make a top five list, but it definitely deserves an honourable mention when it comes to wheat beers. Decoction mashing is traditional and recommended by proficient weizen brewers, but various side-by-side comparisons by various brewers and clubs have demonstrated mixed results in the primacy of decoction. A single infusion mash has beaten decoction in a couple of blind taste tests in several instances. Therefore, do I recommend doing a single decoction mash step from a protein rest at 55°C to saccharification at 65°C? No, I don’t, but you can if you want. My experience is that you can brew excellent weizenbier with a single infusion mash at 65°C.

The scientific purpose of the decoction was to improve protein breakdown and extract yield in historical malts. This improved breakdown is accomplished during malting in modern malts, and therefore the single infusion probably achieves almost everything the brewer could want from the decoction, except the intangibles. If you want to experience these intangibles for yourself, then decoct and enjoy it!

Fermentation character

Now we come back to fermentation and the ester and phenolic character of these beers. Weizen beer yeast is a POF+ group of strains, which produce the clove-like phenolic characters. The clove/phenol character comes from the conversion of ferulic acid in the malt to 4-vinyl quaiacol (4VG). Mashing in at 45°C for 15 minutes can enhance the production of ferulic acid and help ensure a robust clove character, but again, many gold medal hefeweizens have been brewed with single infusion at 65°C.

There is not much published on the water profile and mash chemistry for weizens, although a Brewing Weissbier presentation by Schneider Weisse notes that acidification of the mash or wort can lead to suppression of the clove character. Therefore, a softer mineral profile of 50-70 ppm calcium and a slightly higher mash pH of 5.4-5.6 may benefit the mouthfeel and overall flavour of the beer. Generally 5 grams of calcium chloride in 20 litres of low mineral or distilled water will put you in this ballpark.

The yeast pitching rate and the fermentation temperature are important for achieving the proper balance of banana ester to clove for these styles. What you are trying to avoid is an excessively fruity beer, one that is has too much banana, or worse, smells like bubble gum.

These German ale strains should be pitched and fermented at a relatively low pitching rate of 0.5 billion cells per litre per °Plato and at a relatively low temperature for ales, about 17°C. Ester formation by yeast is promoted by yeast stress, or in other words, non-ideal conditions. What this means from a practical point of view is that if you want the ester profile to be “just right” then the conditions should not be too cold or too hot, and that the pitching rate (or “social distancing”) should not be too low or too high. One typical 10g dry yeast packet is about 100-150 billion cells and this works out to about the right amount when you do the math for a 1.048-1.050, 19-20 litre batch. It’s a little on the short side of the recommendation but it has proven to work well. Another important consideration is to let the fermenter warm a couple degrees as the beer ferments and to use an Open Fermentation method as opposed to an airlock. Draping a clean tea towel over the airlock hole for the first three days of fermentation will generally do the trick – allowing oxygen/carbon dioxide exchange while keeping dust and bugs out. The airlock can be replaced after three days as the fermentation winds down and this will prevent any contamination as the beer maturates prior to bottling or kegging. The beer should be maturated in the fermenter at 21°C for a week before bottling or kegging. Bottle conditioning is traditionally preferred.

Brew day

The recipe for a classic hefeweizen is very simple: 60% of the finest pale wheat malt and 40% by weight of the finest pilsner malt, about 12 IBUs of a traditional German hop, German Wheat Ale yeast, and an OG of 1.048 or 12°P. But let’s make this a little more interesting and a little more forgiving by adding some specialty malts and make it a dunkelweizen. Enjoy!

John Palmer’s All Grain Teatime Dunkelweizen

Expected figures

OG: 1.053

FG: 1.014

ABV: 5.1%

IBU: 13

Volume: 19 litres

Ingredients

3kg Wheat malt

750g Pilsner malt

500g Munich II malt

500g Caramunich III (or Carawheat) malt

100g Chocolate wheat malt

200g Rice hulls

12g Mandarina Bavaria hop pellets

Mangrove Jacks Bavaria Wheat M20

Recommended water profile

Ca2 50-100, Mg2 5-10, Total Alk 50-100, SO42 25-75, Cl 100-150, RA 0-50

Method

- Mash in to hit 65°C for 60 minutes.

- Sparge and transfer to kettle.

- Once boiling add all Mandarina Bavaria hops for a 60 minute boil.

- Flame out and whirlpool.

- Cool wort to 17 °C and run into fermenter.

- Oxygenate or aerate and pitch yeast and maintain 17°C during fermentation.

- When FG stabilises, keg or bottle as usual.

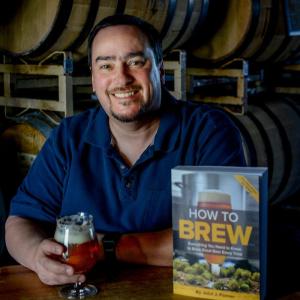

John Palmer is the author of the bestselling home brew book How to Brew. In every issue of Beer & Brewer magazine he does a deep dive into a particular facet of brewing better beer and regularly provides one of his recipes. Subscribe to our magazine here.