I generally don’t like tasting chocolate and coffee beers in competitions, but that’s not because I don’t like the flavours, because I do, but the reason is the off-flavours.

The problem is that coffee and chocolate beers generally don’t have a long shelf life as they contain oils that quickly oxidise and end up tasting like old coffee or oxidised chocolate. Despite this statement of doom, I have tasted, awarded medals and actually purchased both chocolate and coffee beers many times over the years so it is indeed possible to brew them with stable flavours.

The secret to brewing with spices is to not boil them. Boiled spices end up tasting very astringent, especially the woody spices like cinnamon and cloves. In general, spices respond best to hot steeping in the wort, just like whirlpool hop additions. The warm or hot temperatures help release the oils that give these additives their characteristic flavours, and the pH of the wort usually prevents astringency and bitter notes.

There is a general trade-off between temperature, flavour and aroma when steeping spices: hotter steeping temperatures release more flavour and cooler temperatures release less but retain more aroma. When you think about it, it sounds just like the trade-off between whirlpool hop additions and dry-hopping – and that’s because it is. Hops, after all, are essentially a spice that we add to beer.

More is more

Most spices should be used in small amounts, generally about 5 to 10 grams for a 20 litre batch size. Delicate or highly volatile spices, like vanilla, should be added after fermentation. But coffee and chocolate are the exceptions to these rules. These flavourings should be used at much higher levels, such as 50 to 250 grams per 20 litres to get good depth of flavour.

As I said at the beginning, the problem with both coffee and chocolate are the oils. For coffee, the general solution is to cold steep coarsely ground beans, either at room temperature (for about 12 hours) or in the refrigerator (about 24 hours). Of course, you don’t just want to pour the coffee grounds directly into the fermenter. It’s best to steep the coarse ground coffee in a pitcher and then strain it after steeping and gently pour this coffee into the fermenter towards the end of fermentation.

Opinions vary on how concentrated the coffee should be. A typical cup of coffee has a specific gravity of about 1.005 to 1.010, and is typically brewed at a concentration of about 16:1 water weight to coffee weight. At lower ratios, such as 8:1, the specific gravity can be up to about 1.012 to 1.016, depending on the grind. Generally, you are trying to get the most coffee flavour with the least amount of coffee added. A typical cold brew ratio of 8:1 seems to do a good job, but do you really want to add 2 litres of coffee to your brew? A lower ratio of 4:1 or 6:1 can cut back on the volume.

One common off-flavour in coffee beers is 3-isobutyl-2-methoxypyrazine, which smells like green peppers or mashed green peas. This chemical is not hazardous, but it can dominate the aroma of your beer, and that can be disappointing when unwanted. This pyrazine compound is thought to be formed by enzymatic reactions in the growing bean, and to therefore be dependent on coffee variety and climate. The compound is said to not be significantly affected by roasting. Therefore, you can brew and smell the coffee to look for this compound before you add it to your beer.

Dosage rates for coffee and chocolate

| Flavouring | Batch dosage | How |

| Coffee | 20-25g per litre | 6:1-8:1 w/w Water:Coffee |

| Cocoa powder | 10-20g per litre | Add to boil (10-15 minutes) |

Chocolate is a very popular brewing spice but there are a couple of things to know. First, the fats that are naturally part of the cocoa bean will oxidise and taste bad in the beer, so the less of those, the better. Cocoa nibs tend to be popular with brewers for adding chocolate flavour because they are “minimally processed” and taste good. The problem is that they still have a fair amount of fat: “minimally processed” is one of those industry buzzwords that make you think it is somehow better or higher quality, but there is a reason we process cocoa nibs into cocoa powder – to get rid of the fat and improve flavour stability. High quality cocoa powder is essentially concentrated cocoa nibs, which have been de-fatted by pressing. “Natural” cocoa powder has a lower pH (~5.1) and a more reddish color than Dutch-process cocoa powder (~7 pH). The difference between these types is important when baking and using either baking soda or baking powder for leavening (natural for baking soda, Dutch for baking powder). But the distinction doesn’t matter in brewing. It is unlikely that you would be adding enough to affect the pH of the wort. Cocoa powder doesn’t dissolve into the wort, it becomes a suspension, and if we are lucky, a colloid. Add it towards the end of the boil to help it disperse throughout the wort for about 10 to 15 minutes. Cocoa powder is the exception to the “don’t boil” rule, but long boils will degrade the flavour. Chocolate syrup is also a good option and won’t settle out as much as cocoa powder can. But be sure to check the label for extraneous and unwanted hydrogenated oils and emulsifiers.

Here’s a recipe inspired by the sweet Mexican coffee, Café de Olla:

Mexican Mocha Stout

All grain/BIAB (expected figures)

OG: 1.066

FG: 1.018

ABV: 6.7%

IBU: 32

Volume: 23 litres

Ingredients

5kg Pale malt

500g Crystal (80L) malt

500g Flaked barley

500g Roasted barley

200g Natural cocoa powder

200g Coarse ground dark roast coffee

30g Centennial hop pellets

10g Ceylon cinnamon stick

English ale yeast of choice

Recommended water profile

Ca2 75-100, Mg2 20, TA 100-150, SO42 50-75, CI 75-100, RA 75-100

Method

- Mash all grains at 67°C for 60 minutes.

- Sparge and transfer to kettle, aiming for 26.5 litres at 1.057, and bring to boil.

- Once boiling add 30g Centennial hops for a 60 minute boil.

- With 15 minutes left on the boil, add 200g natural cocoa powder.

- At 60 minutes, flameout and add the coffee and cinnamon sticks, then steep for 15 minutes.

- Transfer to the fermenter and cool to 18°C, then pitch yeast.

- Maintain ferment temp at 18°C.

- Once FG stabilises, keg or bottle condition.

- Drink this beer fresh so to make the most of the coffee and chocolate aromas.

Extract with specialty grains (expected figures)

OG: 1.066

FG: 1.018

ABV: 6.7%

IBU: 32

Volume: 23 litres

Ingredients

3.5kg Pale extract

500g Crystal (80L) malt

500g Flaked barley

500g Roasted barley

200g Natural cocoa powder

200g Coarse ground dark roast coffee

30g Centennial hop pellets

10g Ceylon cinnamon stick

English ale yeast of choice

Method

- Steep cracked grains in 5L of 67°C water for 30 minutes, then drain.

- Slowly dissolve the extract in 5L of water along with the 5L of wort from mini mash whilst bringing to the boil.

- Once boiling add 30g Northdown hops for a 60 minute boil.

- With 15 minutes left on the boil, add 200g natural cocoa powder.

- At 60 minutes, flameout and add the coffee and cinnamon sticks, then steep for 15 minutes.

- Transfer pot to ice bath to cool the wort or cool wort by other means, then add to fermenter. Be extremely careful if moving the entire pot to ice bath.

- Top up with cool fresh filtered water to reach 23L, check temperature regularly to make sure you hit 18°C.

- Check your temp is 18°C, then pitch yeast.

- Maintain ferment temp at 18°C.

- Once FG stabilises, keg or bottle condition.

- Drink this beer fresh so to make the most of the coffee and chocolate aromas.

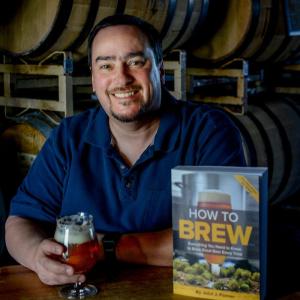

John Palmer is the author of the bestselling home brew book How to Brew. In every issue of Beer & Brewer magazine he does a deep dive into a particular facet of brewing better beer and regularly provides one of his recipes. Subscribe to our magazine here.